Plasma Polishing Machine

Environment Protection

Plasma polishing equipment has been widely used in the industry for things, such as household appliances, catering tableware, medical equipment, and aviation industry, auto industry etc., which can meet food-grade requirements and completely realize the promise of non-toxic and environmental protection.

Plasma Advantages

- Environmental sustainable

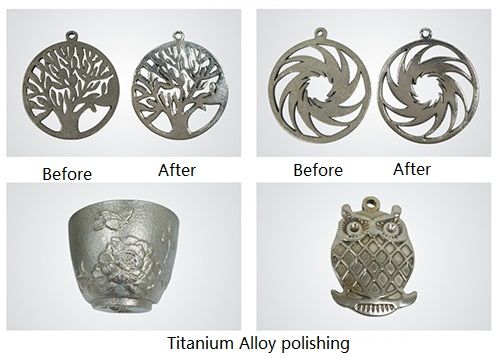

- High quality surface mirror treatments

- One machine equal 37 people workloads

- Plasma density control technology

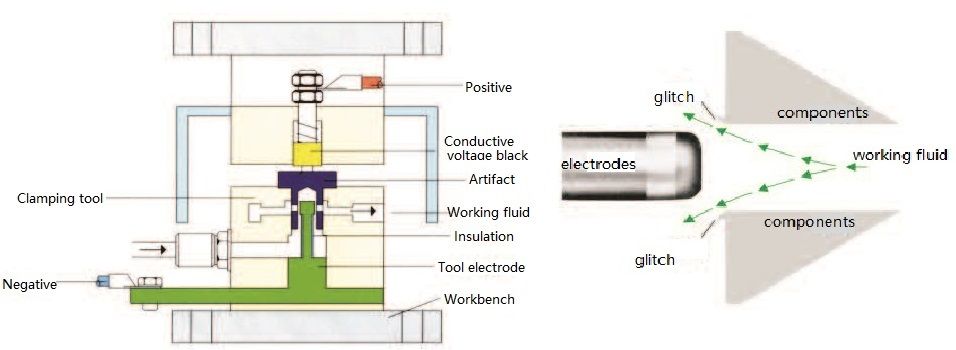

- Cutting-edge discharge technology

- Double membrane molecular replacement

- Ion cluster motion control

- Non-contact conductive technology

- Electrochemical deburring technology

Machine Charecteristics

- Suitable for deburring of inner holes and cross holes of various hardware parts;

- It can replace flame deburring and freezing deburring in traditional processes;

- Applicable to the entire field of metal cutting processing;

- The use of non-linear electrolyte is harmless to the human body

Plasma Polishing Industry Analysis

- In various polishing industries, various metal materials require a large number of polishing personnel, and the price of polishing personnel in the market is relatively high and recruitment is difficult;

- The traditional metal polishing work environment is poor: the dust, noise and other pollution of various jobs are serious, which seriously affects the physical and mental health and work efficiency of the polishing workers;

- Traditional metal polishing work requires high skills: Generally, polishing workers need a training period of three to six months, and the training period will cause a large number of product scraps and high training costs for employees;

- Wastewater and waste environmental protection issues: traditional polishing and corresponding post-processes will bring different degrees of environmental protection issues; our company's plasma polishing equipment and process meet environmental protection requirements, which can effectively reduce environmental protection investment costs;

- Production cycle: The traditional process has a long production cycle. Plasma polishing equipment can greatly increase production capacity and shorten OTD, which is conducive to seizing the market and winning opportunities.

In summary, plasma blasting equipment is the most ideal solution in current and future polishing solutions.

Applicable Industry

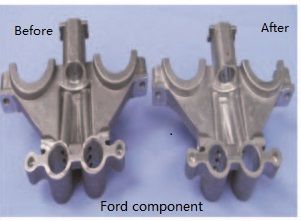

- Automobile engines

- General engineering machinery;

- Aerospace, pneumatic hydraulics;

- Other industries are important equipment;

- For electrochemical processing machine tools that produce large batches and have the widest application fields.

Plasma Polishing Machine Main Parameters

- VOLTAGE: INDUSTRIAL VOLTAGE 380V/600V

- CURRENT: (DIRECT CURRENT) WORK ON 1000A

- POLISHING SALT: ENVIRONMENTAL PROTECTION NEUTRAL

- LIQUID TEMPERATURE: 90C+

Security Guarantee

- Voltage & current overload early warning protection

- Real-time temperature detection and compensation protection

- Safety door protection to prevent leakage and electric shock

Advantages

- Customized manufacture

- 24 hours response to service

- One Year Warranty

- High Technology on Plasma Area

- Strong Engineering Group

- Support over 10 years

- Service to Apple, Samsung…

Contact us to get more details for your needs

Do not miss this machine, the surprise will be unexpected

Our promise

Our highly qualified experts will complete any task fast and reliably.

We guarantee fast and discrete handling of all your business tasks. Our team of highly qualified employees is available day and night – because your satisfaction is our highest priority.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.